Absorption principle

The absorption chiller is based on the physical principle of absorption. We all know that table salt has the characteristic of getting wet when exposed to air; it absorbs water vapor from the air. In the absorption chiller, lithium-bromide salt is used as an absorbent and water is used as refrigerant.Heat is the driving force

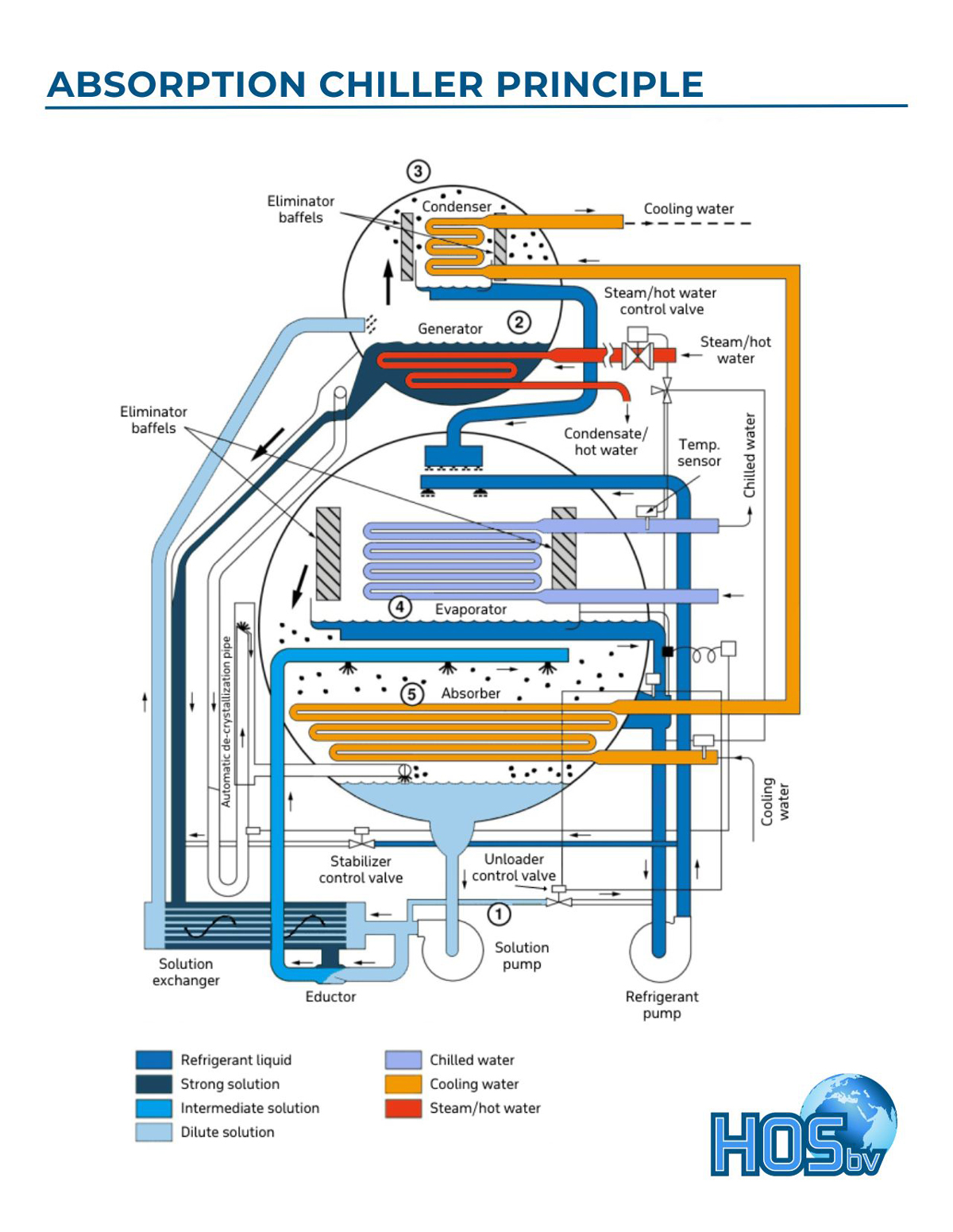

In the absorption chiller heat is the driving force. So, there is no mechanical compressor but just hot water or low-pressure steam.Four heat-exchangers

For continuous cooling, the absorption chiller consists of 4 heat exchangers:- The evaporator where the refrigerant (water) is delivering the cooling.

- The absorber where the lithium-bromide salt solution absorbs the water vapor from the evaporator.

- The generator where water is boiled out of the absorber fluid.

- The condenser where the water vapor from the generator is condensed.

Applications of the absorption chiller

Since this chiller type mainly needs heat, it is attractive when this is available or can be made available at a low cost. In the past, heat was created by burning fossil fuel but nowadays we see the absorption chiller mainly in process cooling where heat is available and cooling is required. This also counts for total energy systems like greenhouses, where the available heat from the gas engine is used to feed the absorption chiller.Typical performance data

- Chilled water temperature is between 12 and 4 °C. Lower is not possible.

- Hot water temperature nominal at 120 °C, performance derate when lower, minimum around 90 °C.

- Heat input is 1,4 times the cooling capacity.

- The cooling water requirement is around 2,4 times the cooling capacity.

HOS BV adds value by support in engineering and equipment selection.