A complete refrigeration system

The most common and thus by far the most produced is the packaged air-cooled chiller for outside installation. This means that the chiller is produced and installed as an “all-inclusive” black box containing a complete refrigeration system with its safeties and controls to deliver cooling capacity. The chiller is connected via supply and return piping to installations inside a building. The purpose could be for air conditioning, process cooling or cold storage.Chiller components

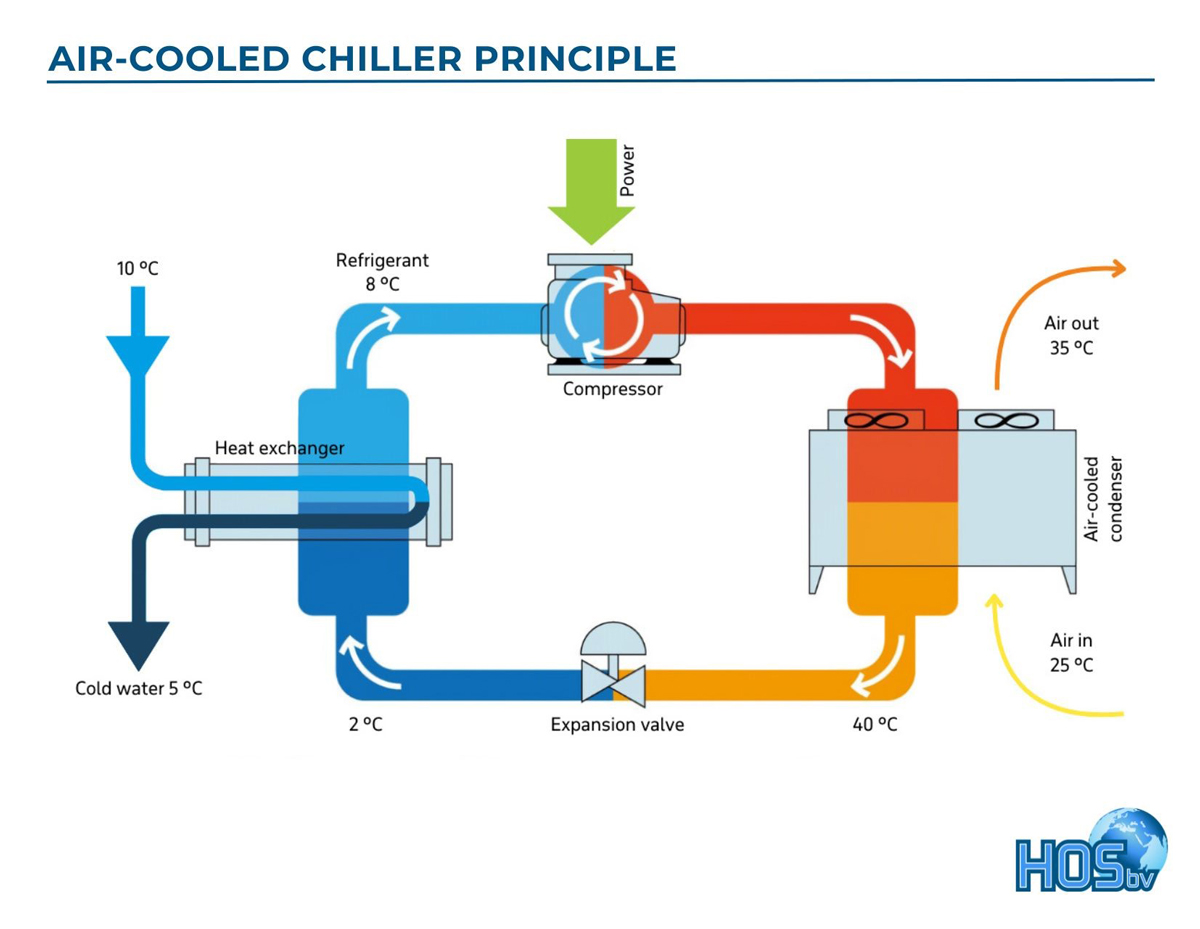

The chiller contains a refrigeration circuit containing four main parts: Compressor, evaporator, condenser and expansion valve. The evaporator (which is the part where the water is cooled) can be either a so-called “shell and tube” type or a plate heat exchanger. For the air-cooled chiller, the condenser ( this is the part where the heat is moved to outside air) is a finned coil where ambient air is blown through for the air-cooled types. The expansion valve can be thermostatically controlled or controlled via an electronic circuit.Compressor

The compressor type depends on the unit size. For small capacities (up to around 200kW) most common are (multiple) hermetic compressors either reciprocating type (piston) or rotary type (scroll). On larger units, you see semi-hermetic compressors either reciprocating or rotary (screw) type. Multiple compressors on multiple refrigerant circuits are standard to keep cooling capacity in case of failure of one circuit.

Capacity range

For the air-cooled units, the cooling capacity ranges from around 50kW up to 800kW. The limitation is what size can be transported on a standard lorry. For large-capacity applications, multiple units are used.Temperature range

The temperature range on the chilled water side is normally from 5°C up to around 20°C. Lower temperatures are possible by using a suitable water anti-freeze mixture, mostly ethylene or propylene glycol mixture. Limitation depends on the model and make but is typically in the range of -6°C to -10°C.

Interchangeable

As said before, the packed air-cooled chiller can be seen as a black box that cools a waterflow. Selection criteria are the required cooling capacity, water temperature and water flow. And of course size of the electrical connection. This means that an existing unit can, in case required, simply be replaced by a similar unit of another brand. This is a very important characteristic.Reliable

Packaged chillers have long been available from an extended range of manufacturers. Some use standard and commercial market available components, and some design and produce their own parts which are used to build the units. The design of each unit of any make is based on years of experience. In general, we can say that all makes and models are well-designed and ready for many years of trouble-free operation.HOS BV can deliver a wide range of chillers in all applicable capacities, sizes and makes, from stock or with a very short lead time.