Challenge:

A Freezing Solution for Quality and Productivity Challenges

The Soy Bean Company was established in 1969 and has always produced the well-known Indonesian food staple Tempeh from soy beans. It also produces fermented soy bean cubes and did this in batches in a blast freezing process.

This meant product sometimes stayed too long out of the freezer diminishing the quality of the product. And as blast freezing is a start-stop batch process the customer also started to face productivity issues.

These issues needed to be resolved simultaneously and therefore Schindler Consulting was contacted to design a solution that would take care of both issues.

Solution:

Efficiency Meets Space Constraints with Bitzer OSNA compressor set

Schindler Consulting reached out to HOS BV and technical discussions were started, cooling capacity calculations made and all other requirements taken into consideration.

One of those requirements was that the solution needed to be as compact as possible, given space restriction in the Soy Bean Company production facility.

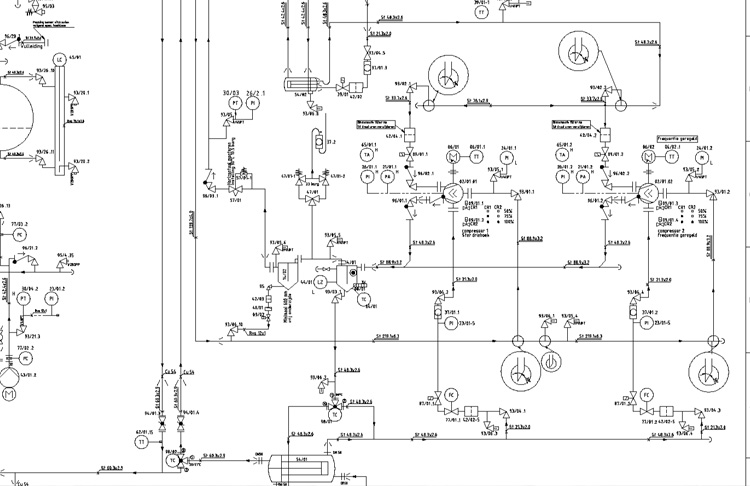

Out of the engineering process came a Frigoscandia Gyrocompact Spiral Freezer, a Bitzer compressor frame with 2 pieces OSNA 7471K screw compressors and a capacity matching air cooled condenser.

Result

When a Spiral Freezer is sometimes the answer to all your questions

After approval of the technical proposal and agreement on the Commercial terms and contract signing HOS BV started to prepare the equipment.

Performed Services:

- Belt- and drum drive systems for the Spiral Freezer fully tested and evaporator fans tested and bearings replaced, whilst pressurizing the coil for leak testing.

- Compressors were fully overhauled and condenser fans were tested and bearings replaced and coil pressurized for leak testing.

- After thorough industrial cleaning the equipment was delivered to the customer site and Schindler Consulting took care of the installation.

Soy Bean Company have boosted their productivity and improved the quality of their finished product as a result of this joint effort. Now that has been converted to a continuous process eliminating a lot of extra handling and human intervention.

Installed early 2021 the installation is running to date without any significant issues much to the content of the customer.